Our off-road vehicles are frequently subjected to intense use and conditions. Some original parts capitulate to excessive abuses and sooner or later, a replacement must be made. Among these, the CV joints are at the top of the list of parts needing to be tossed. If you’re going to do it, you might as well go with heavy-duty CV joints of superior quality.

The users who submit their ATVs or UTVs to tortures beyond the limits of the stock parts can now upgrade their CV joints with parts of higher quality. Rhino axles raise the established standards to a whole new level. They are made from very strong 4340 Chromoly steel which is one of the strongest materials in the industry. With an excellent strength/ weight ratio, these axles are designed for combat! They exceed expectations and offer performance that is not found in original axles or in the other aftermarket parts. Each CV joint and shaft are optimized for ultimate strength. Each joint is protected by a puncture-resistant TPE (thermoplastic polyester elastomer) boot. The Rhino brand axles leave no detail to chance – synthetic grease is used to keep them cold and well lubricated every time they have to be submitted to rough environments. Each axle is precision engineered to provide the ultimate balance of strength and durability.

Whether they are used with oversized tires, a set of tracks, on difficult terrain or on a power-boosted vehicle, they are designed to withstand the harshest conditions. Their angle of articulation is superior compared to original equipment. This feature combined with a set of suspension lift kit is also the perfect fit for tackling impossible obstacles and coming out of deep muddy holes.

The replacement of a CV joint by a higher quality axle assembly is possible with a few tools PARTand in a short time. It takes about 30 to 45 minutes to complete this task. Here are the steps to perform this upgrade on your vehicle:

Replacing a rear-wheel CV joint on CFMOTO ZFORCE:

1- Raise your vehicle

Secure your vehicle on a level surface and lift it with a hydraulic jack. Consult your vehicle owner’s manual to find the right lift spots to properly lift your vehicle. Make sure you choose these locations on the frame.

Check again that the vehicle is in “P” mode (Park) and the parking brake is engaged before lifting. Then you will have to remove the real wheels.

2- Remove the cotter pin from the axle nut

If your vehicle is equipped with a cotter pin that secures the axle nut, you will need to remove it. The pin looks like a hairpin with the ends bent to hold it in place. You will need to use pliers to straighten the two curved ends of the cotter pin before you can remove it. If the pin is stuck, try spraying a bit of penetrating lubricant. The lubricant should also help remove the axle nut.

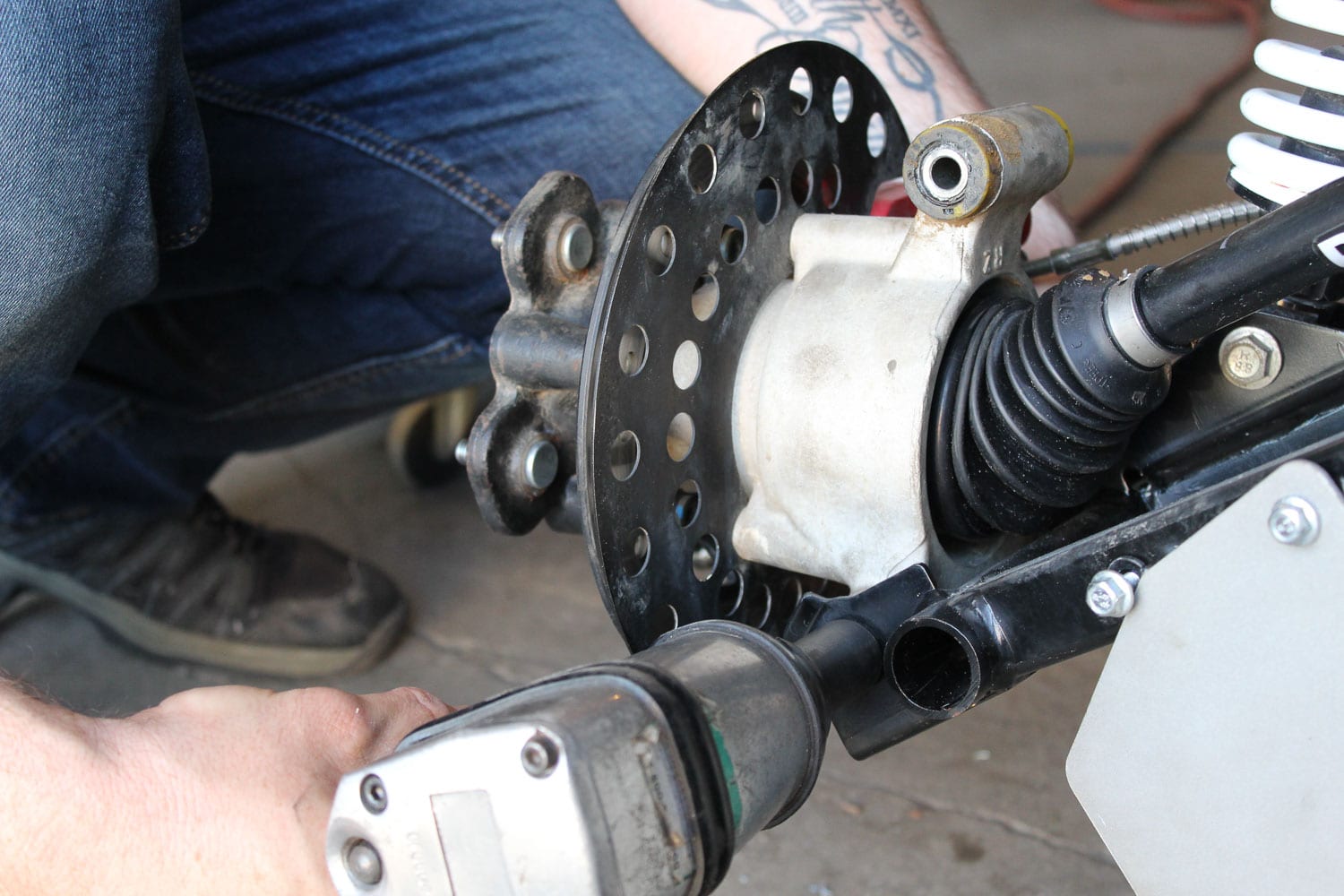

3- Remove the axle nut

Once the cotter pin is removed, you can remove the axle nut. Sometimes it takes a lot of force to loosen the nut. For this reason, the use of an impact power tool is recommended for this operation. In the event that your CV joint is damaged, request the assistance of a helper to apply the brakes while you accomplish this step; this would be very handy.

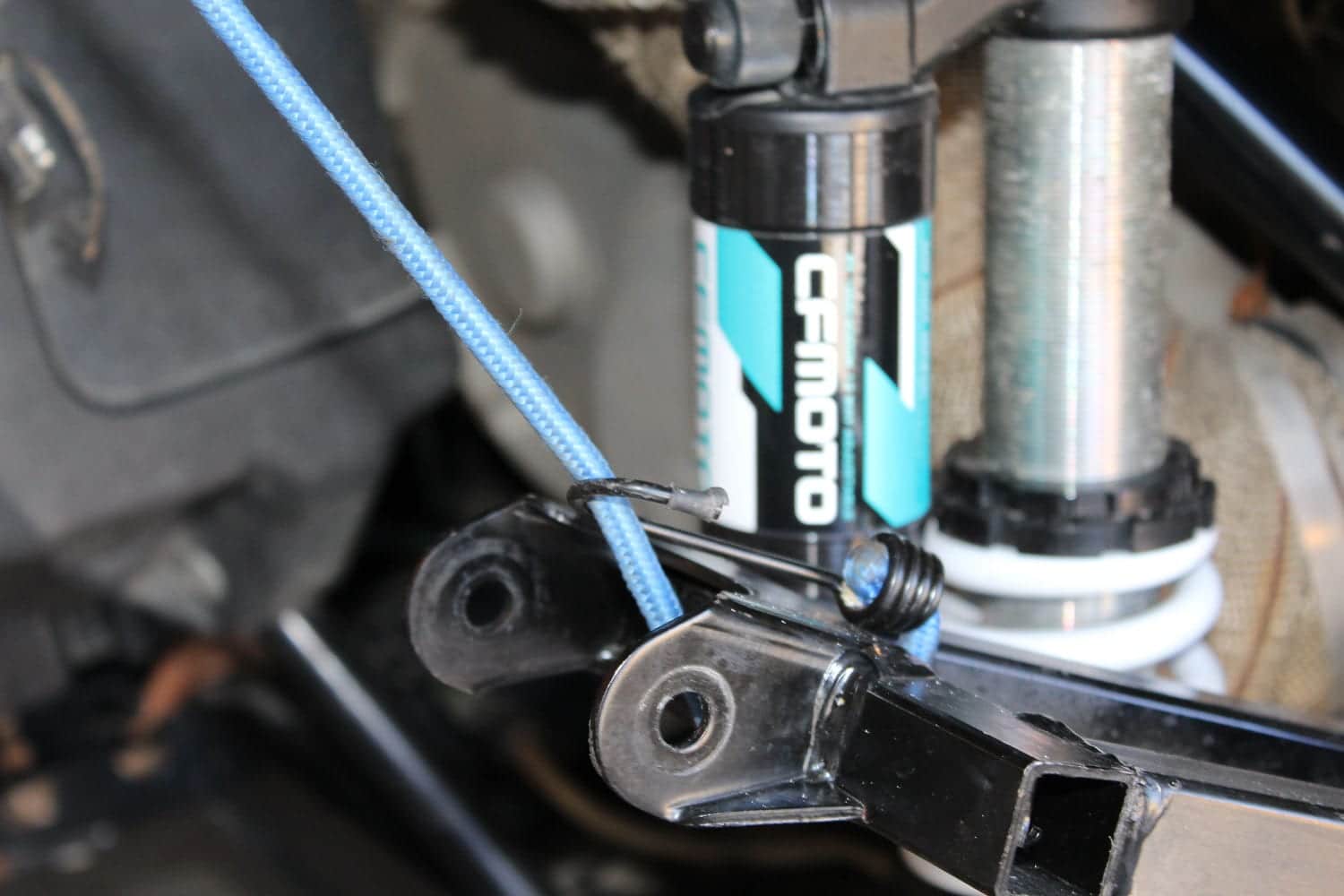

4- Release the stabilizer bar

To facilitate the following steps, the stabilizer bar must be unbolted, this would allow the release of the upper triangular arm in a subsequent step.

5- Remove the wheel shaft support

The upper and lower bolts must be removed at this stage, as it will be possible to remove the axle by removing the support, the wheel hub, and the brake rotor.

6- Release the upper triangular arm

To facilitate the next steps, the use of a bungee cord to lift and secure the upper triangular arm is recommended. This would make more space to complete the following work.

7- Remove the axle

Remove the CV joint end from the support and wheel hub, and then make sure the axle is horizontal and make a pushing motion and a slight twist towards the differential. You will feel a slackening and then you can proceed to its removal. It is normal that transmission fluid leaks when you remove the axle. You should prepare a suitable container for this.

8- Insert the new axle into the differential

At the end of the CV joint, you will find a small C-clip. This clip holds the axle in place in the differential. To facilitate the insertion, we recommend the use of bearing grease to help retain the C-clip in place. Now insert the new axle at the same location in the differential. The tip end will slide fully in place until the axle is flush with the housing.

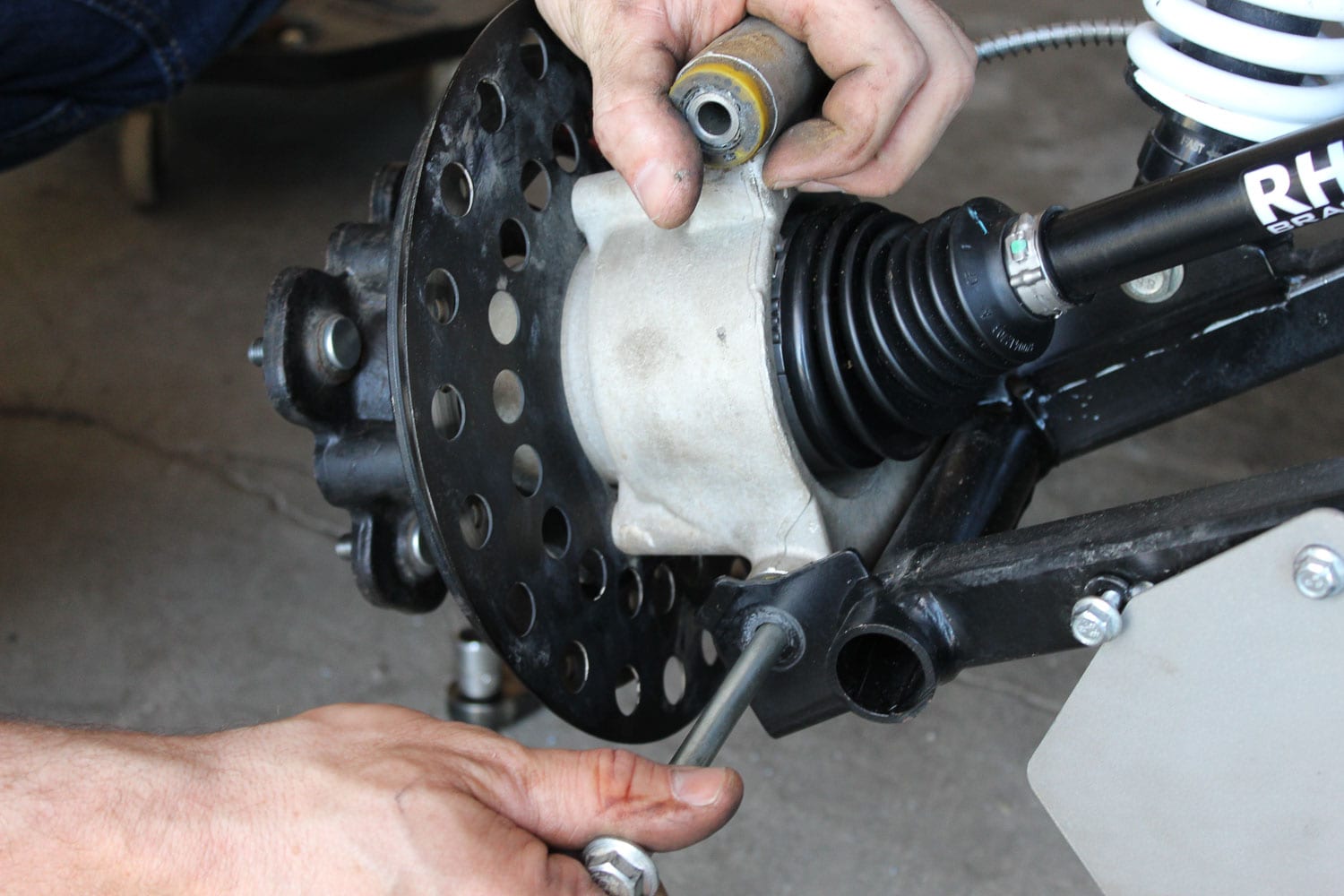

9- Reinsert the axle in the support and the wheel hub

The new axle must be reinserted in the center of the hub assembly at the same location where you removed the original axle. Make sure the tip end is properly seated on the differential surface and check that the C-clip is well engaged by testing its strength with a slight pull test.

10- Assemble of the upper and lower triangular arms

Reinstall the triangular arms to the wheel axle bracket using the previously removed bolts.

11- Installation of the axle nut

Reinsert the nut and hand tighten. Then use the impact wrench to set it up.

12- Install the cotter pin

The old cotter pin may be damaged, so you should replace it with a new one rather than reuse the old one. Insert the pin, and using a flathead screwdriver, separate the end. Finish separating the end of the pin using pliers.

13- Put back the wheels

At this point, you can put the wheels back on the vehicle (the same way you would when changing tires). Once the wheels are in place, you can lower the vehicle from the jack.

Note: These steps may differ from one vehicle to another. When replacing a CV joint of a front wheel axle, the difference is in the fixing point of the wheel axle support: disassemble the ball joints and tie-rod.

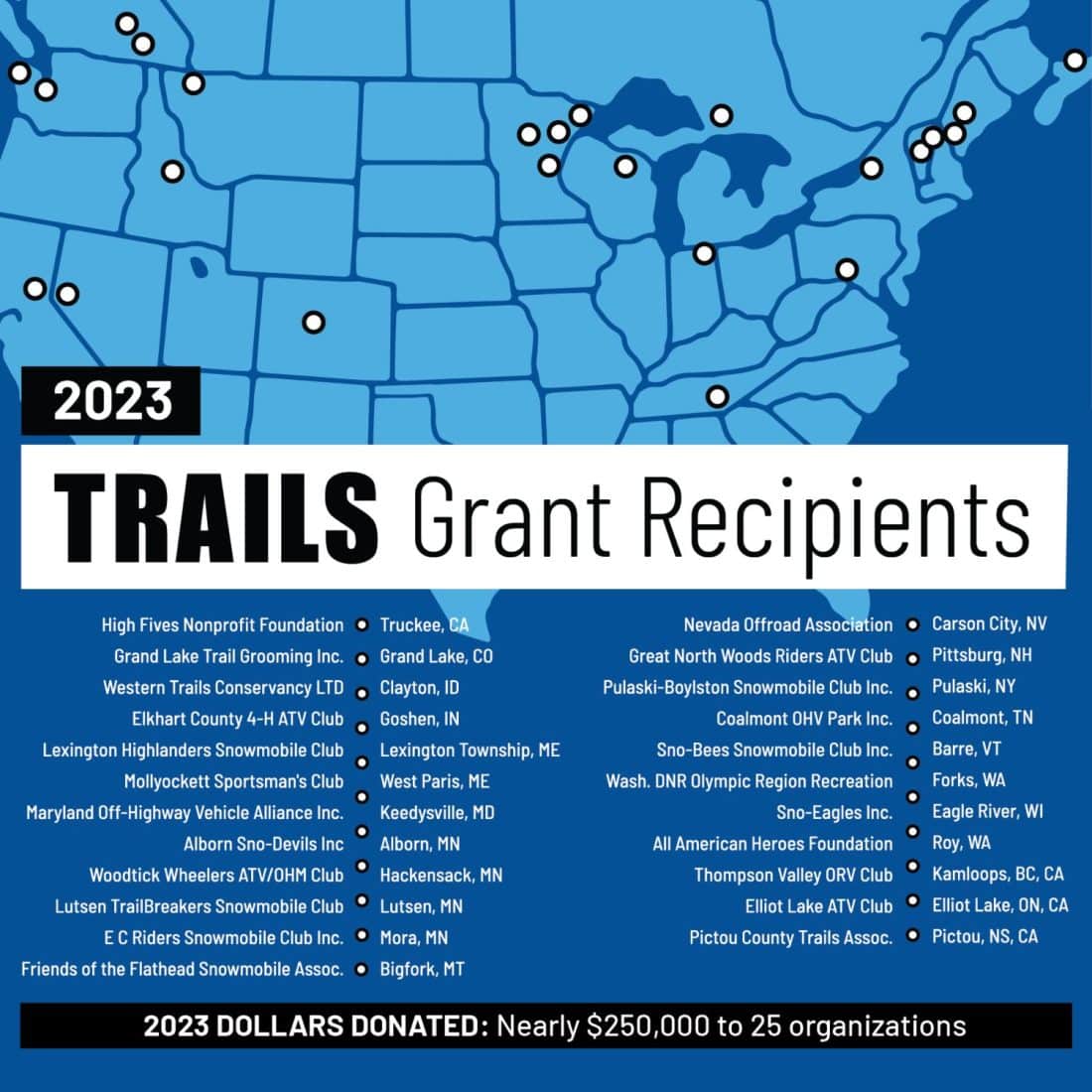

Rhino CV joints are designed for use that will allow you to tackle obstacles and muddy holes with confidence. They also have the advantage of having a 1-year replacement warranty. Get your tools and enjoy sturdy CV joints that will be up to your hardest riding conditions.